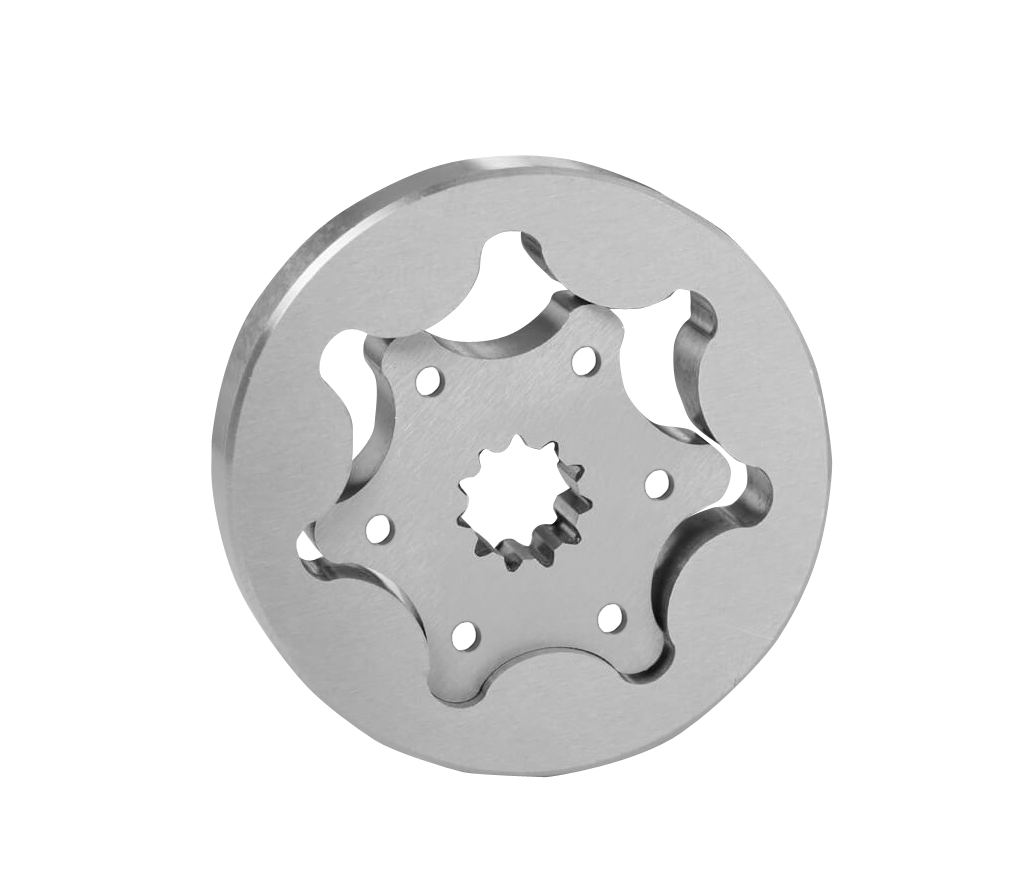

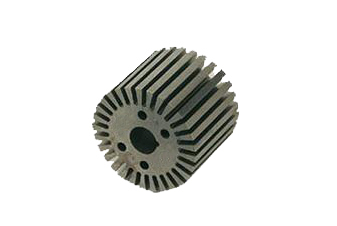

WIRE EDM SERVICES

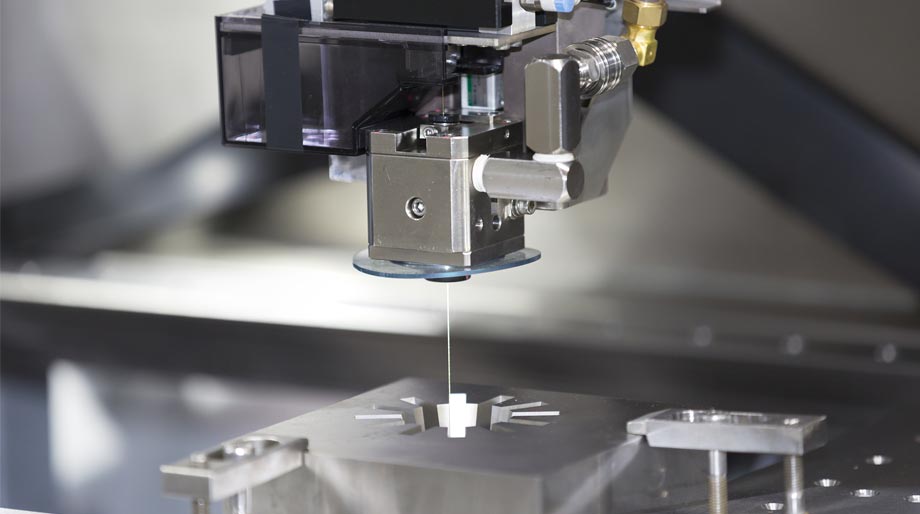

The thin-wired electrode has typical diameters ranging at 0.10mm – 0.30mm (.004″ – .012″), whereas larger and smaller diameters are available. The toughness of the work material does not detrimentally affect cutting speed. No physical contact exists between the wire and the machined part. Instead, the wire is rapidly charged to a voltage; it’s immersed in de-ionized water. As the voltage reaches a correct level, a small portion of the worked piece is melted by a spark; as the de-ionized water cools down, it flushes away from the gap any small particles.

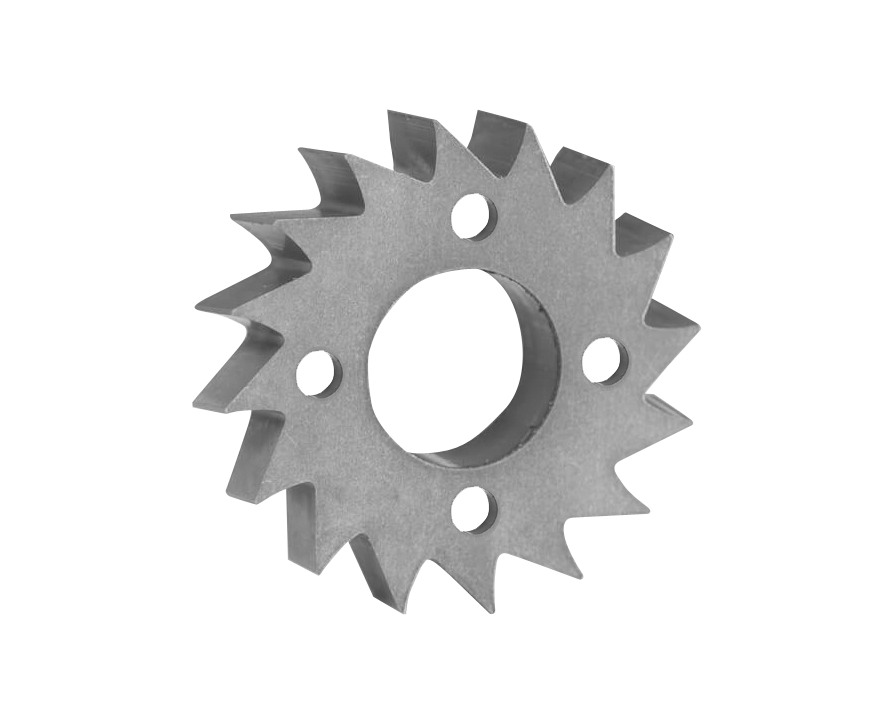

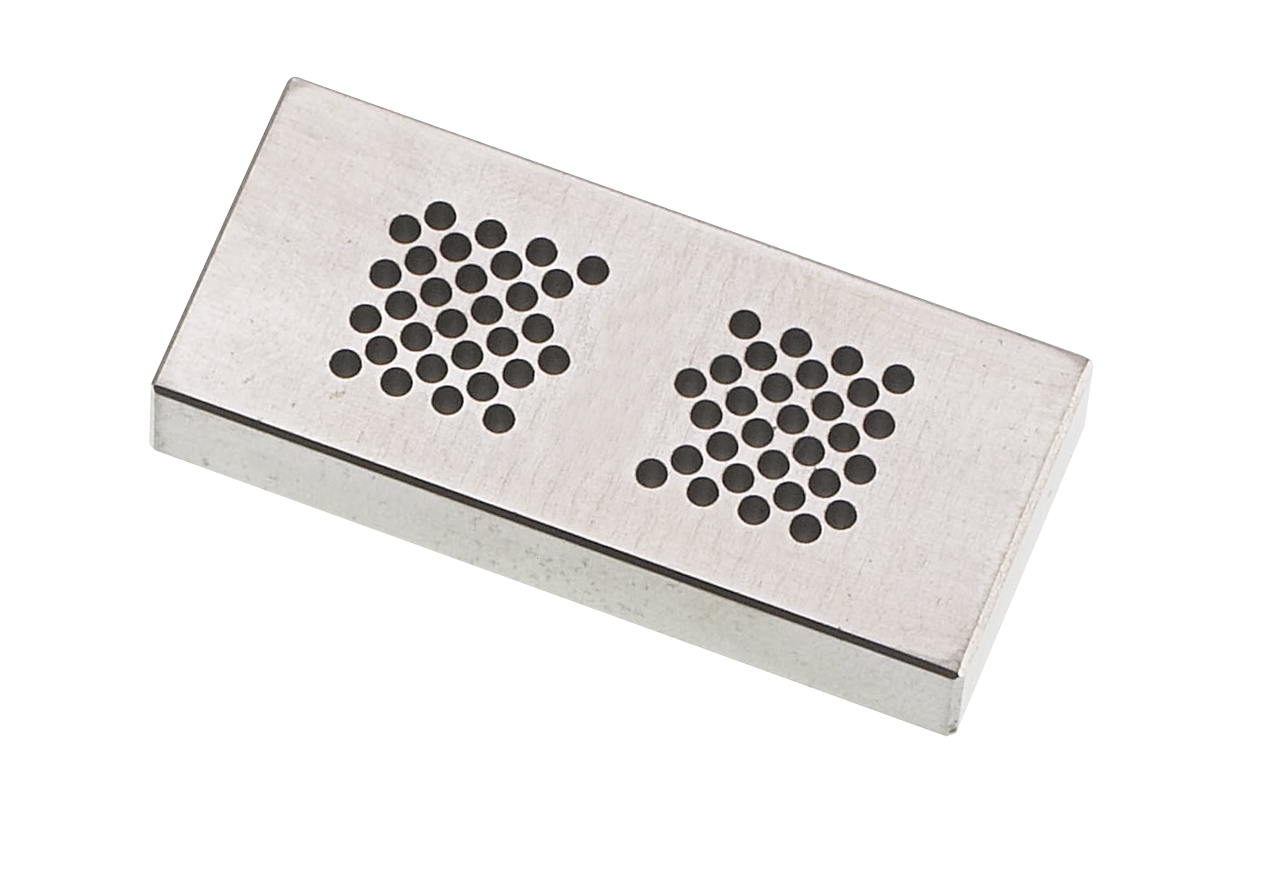

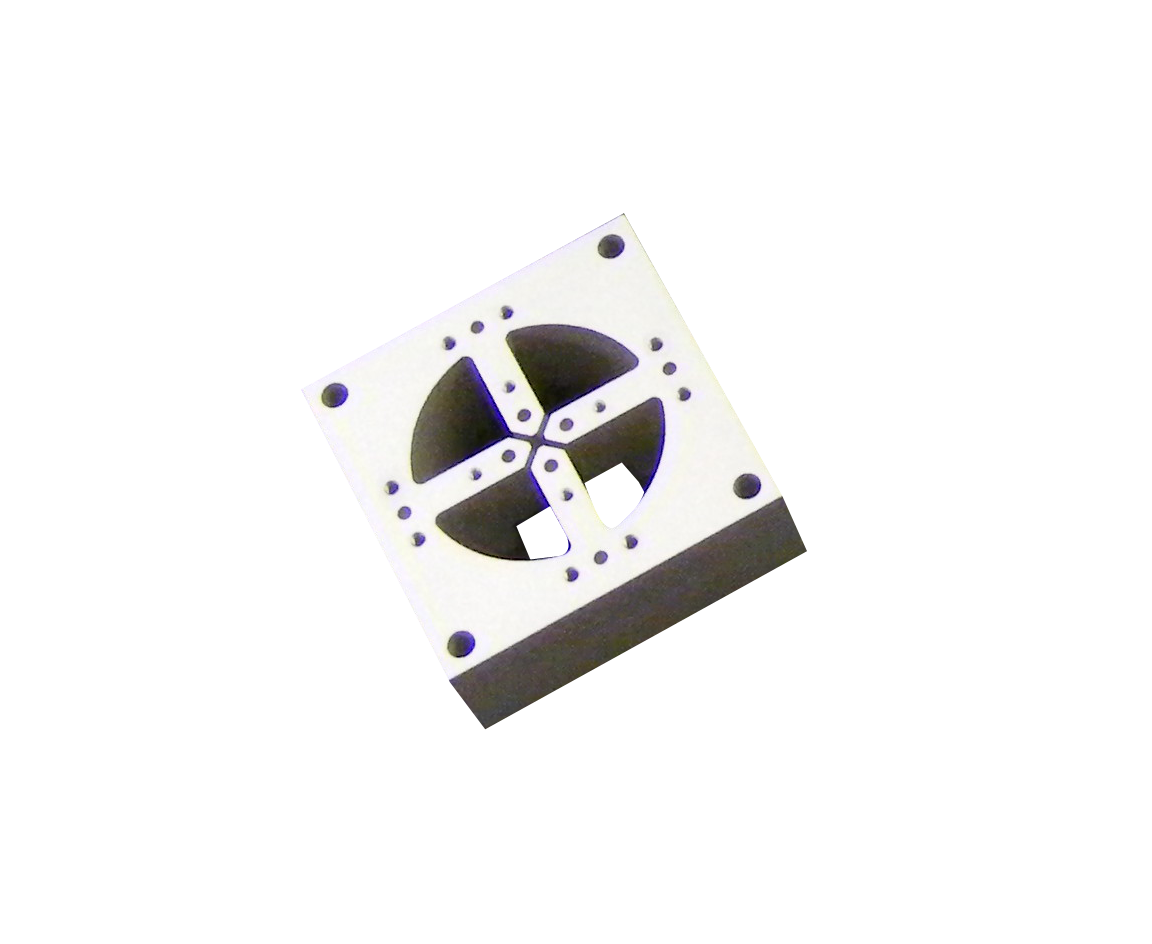

Here at Microtec, we maintain a selection of electrical discharge machining machines, which contain Wire EDM services, CNC Sinker EDM and Small Hole EDM drilling machines. This constellation enables us to derive great precision parts for various applications, in the required amount of time. EDM process allows for cutting any type of conductive material, including common metals i.e. aluminums, stainless steels and tool steels, as well as exotic metals i.e. carbide, inconel, kovar, brass, copper, hastelloy and titanium.