Tank washing nozzles

Tank washing is a typically time-consuming and expensive job that is rampant in many industrial applications. Reactors, storage tanks, process vessels, and process equipment can vary considerably in multiple aspects across industries. However, it is an important sanitary action before or after use of the tanks that prevents contamination of products.

Correct spray nozzles facilitate washing applications using proper distribution of cleaning materials with maximum impact, and reduce operating and disposal costs and save significant time and money. Tank washing can be performed by various nozzles types that utilize available resources to meet all conditions and requirements.

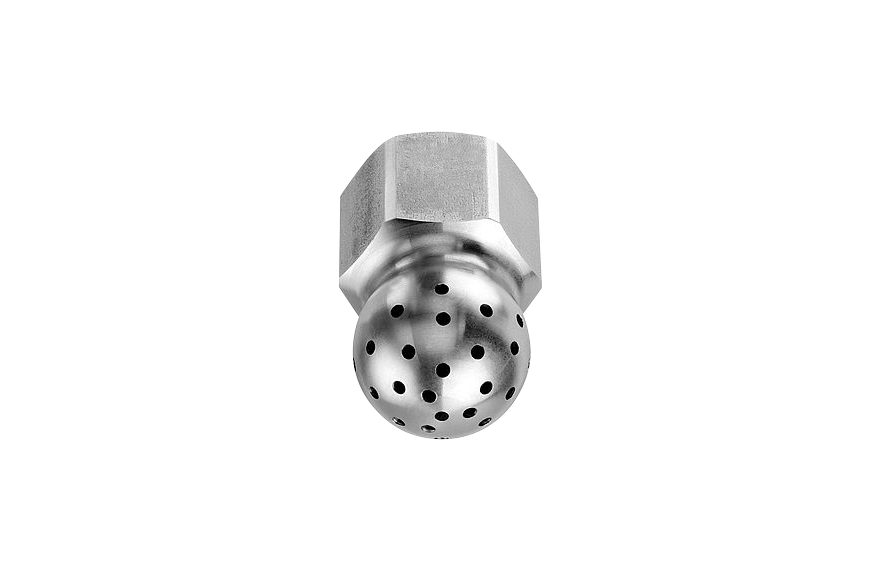

- Static spray nozzles: these stationary nozzles distribute the cleaning fluid through a number of directional means (i.e. spiral). The fact there are no moving components makes them typically durable, clog resistant and reliable. However, they generally require large flow rates to distribute the fluids correctly on the entire surface with the least amount of impact in washing applications.

- Rotating spray balls: the spinning heads of these nozzles rotate by the force of the cleaning liquid leaving the head. These rotating spray balls are significantly more efficient and require much smaller amounts of cleaning fluid or less time than static nozzles. The rotation rate of these nozzles is dependent on the reactionary force of the fluid exiting the nozzle.